Morning everyone,

I've scoured the internet for the dimensions of the BP4W intake manifold flange but haven't come up with anything.

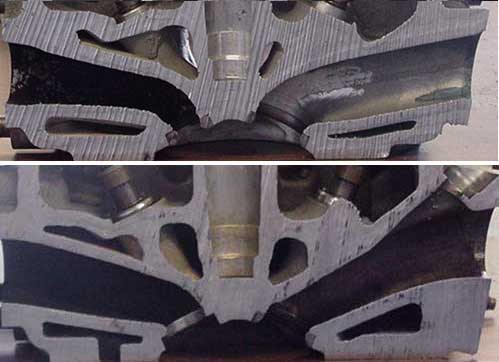

I'm designing a slide throttle, plenum and manifold but don't have access to an engine to strip and measure so progress is coming to a halt.

This particular slide throttle is to be suited for both NA and boosted engines which I don't believe has been done before.

Version 1 (now on v3)

If anyone has the dimensions to hand or even a solidworks file I would be grateful. Also is the manifold canted upwards like on the Toyota 2zz engines?

I apologise if this has been asked before (I did search on this forum first!)

Thanks,

George

P.S - it's my first time, be gentle.

I've scoured the internet for the dimensions of the BP4W intake manifold flange but haven't come up with anything.

I'm designing a slide throttle, plenum and manifold but don't have access to an engine to strip and measure so progress is coming to a halt.

This particular slide throttle is to be suited for both NA and boosted engines which I don't believe has been done before.

Version 1 (now on v3)

If anyone has the dimensions to hand or even a solidworks file I would be grateful. Also is the manifold canted upwards like on the Toyota 2zz engines?

I apologise if this has been asked before (I did search on this forum first!)

Thanks,

George

P.S - it's my first time, be gentle.