Bit of background:

By default, Mk1 (Mk2 uses a different system with knock sensors) and MX5 are set to 10 degrees before the top dead centre (BTDC) from the factory. What this means is that just before the piston reaches the top of the stroke (think of a degree as an amount of time before this happens for the sake of simplicity), the spark plug will fire for a given cylinder. This is a critical point because if the plug fires too early, the mixture will try to ignite when the piston is traveling up in the bore and the flame front (the blowing up stuff) fights against the crown (top) of the piston which is just bad news.

Conversely, if the ignition timing is too late, you can get a different problem, spontaneous combustion. Basically, the air-fuel mixture in the cylinder just blows up before the spark gets to ignite it correctly, also bad news.

The good news is that the MX5 is set up to deal with a range of different fuel qualities as low as ~90 RON. Thankfully here in the UK, even supermarket fuel is 95 RON which is more resistant to detonation. This means we can ignite the mixture earlier which means you have more energy forcing the piston down from the top of the stroke. This makes for big bangs and lots of smiles on the happy driver's face

OK, that's enough talk, this is how you do it:

Step 1 - Run the car to normal operating temperature to start with

![MXTMStep1.jpg MXTMStep1.jpg]()

Step 2 - Pull the bonnet and start to poke around in the engine bay

![MXTMStep2.jpg MXTMStep2.jpg]()

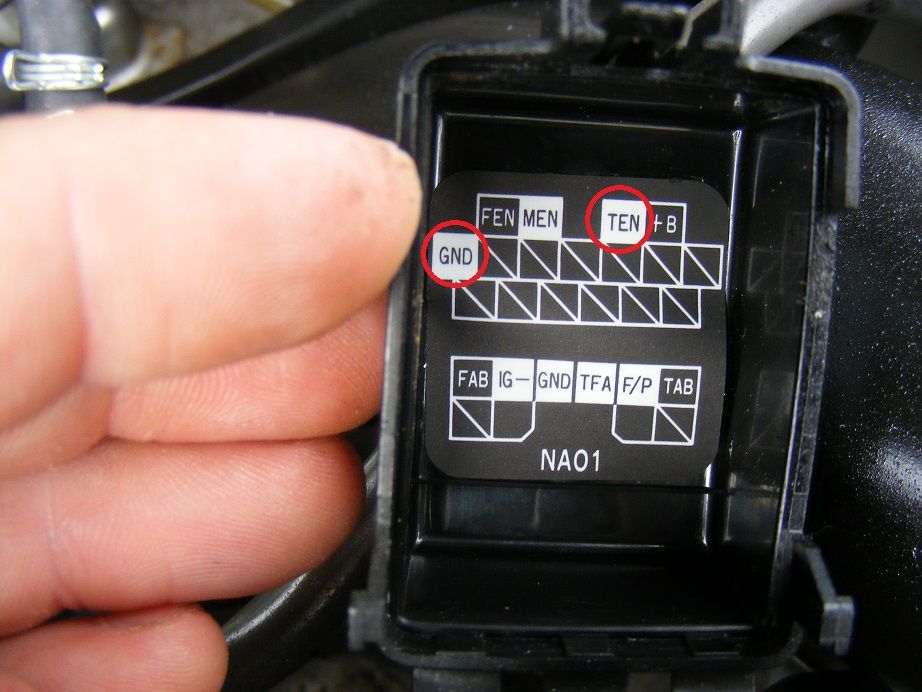

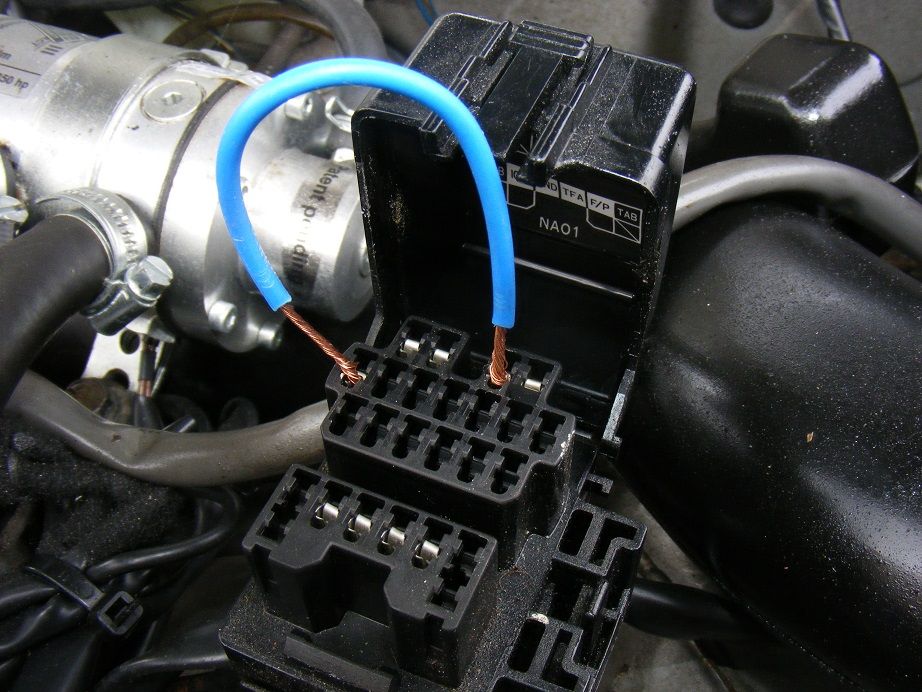

Step 3 - Locate the diagnostics box (the small black box that, helpfully, says diagnostics on it on the nearside inner wing)

![MXTMStep3.jpg MXTMStep3.jpg]()

By default, Mk1 (Mk2 uses a different system with knock sensors) and MX5 are set to 10 degrees before the top dead centre (BTDC) from the factory. What this means is that just before the piston reaches the top of the stroke (think of a degree as an amount of time before this happens for the sake of simplicity), the spark plug will fire for a given cylinder. This is a critical point because if the plug fires too early, the mixture will try to ignite when the piston is traveling up in the bore and the flame front (the blowing up stuff) fights against the crown (top) of the piston which is just bad news.

Conversely, if the ignition timing is too late, you can get a different problem, spontaneous combustion. Basically, the air-fuel mixture in the cylinder just blows up before the spark gets to ignite it correctly, also bad news.

The good news is that the MX5 is set up to deal with a range of different fuel qualities as low as ~90 RON. Thankfully here in the UK, even supermarket fuel is 95 RON which is more resistant to detonation. This means we can ignite the mixture earlier which means you have more energy forcing the piston down from the top of the stroke. This makes for big bangs and lots of smiles on the happy driver's face

OK, that's enough talk, this is how you do it:

Step 1 - Run the car to normal operating temperature to start with

Step 2 - Pull the bonnet and start to poke around in the engine bay

Step 3 - Locate the diagnostics box (the small black box that, helpfully, says diagnostics on it on the nearside inner wing)